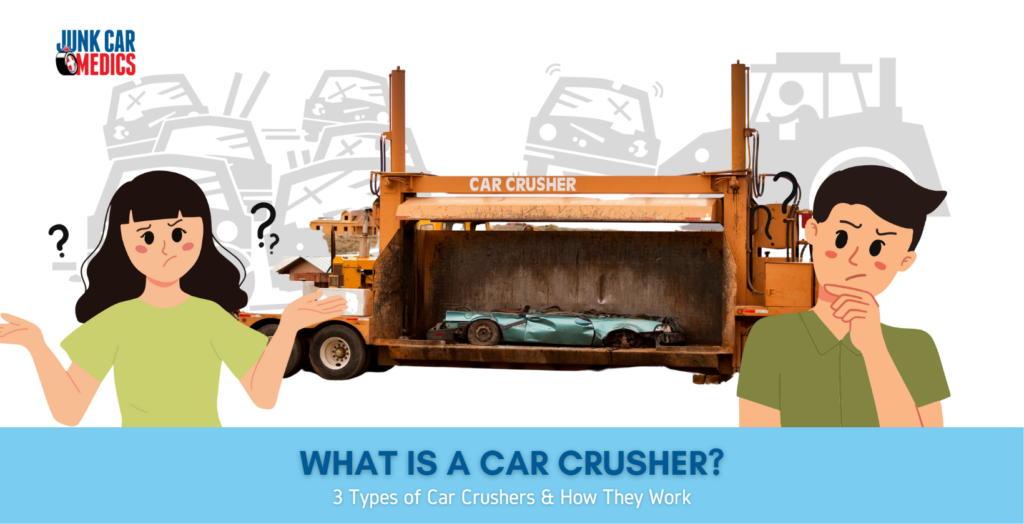

A car crusher or automobile crusher is a machine that reduces a vehicle's shell to take up less room. Modern car crushers use a combination of hydraulic pistons and plates to produce a flattened car.

By reading this article, you will gain an opportunity to learn more about these aspects of car compactors.

What are the types of Car Crushers?

Even though all car crushers do the same job, there are different mechanisms to achieve the same goal.

In the case of car crushers, there are three basic types:

1. Mobile Car Crushing Machine (alt: mobile car crushing machine)

A mobile car-crushing machine is a vehicle-crushing machine that can be transported from one place to another.

Their fundamental design follows stationary car crushers. While most use horizontal and vertical plates to crush vehicles, others may shred the metal instead of using hammers.

A mobile crusher must be smaller than stationary crushers to move along roadways. According to torqueguru.com, the crusher unit has guideposts that ensure the plate applies even pressure across the vehicle.

Since these guideposts are limited in size because of traffic considerations, a mobile car crusher cannot be used for vehicles above a certain size.

Powering a Mobile Car Crusher

According to eaglecrusher.com, industrial vehicles, and other mobile crushers utilize diesel engines to power an electric generator.

This generator, in turn, powers several motors that:

- power magnets that position the vehicle within the crushing chamber.

- Pressurizes fluid in hydraulic chambers to raise and lower the crushing plate.

- Move the metal along a conveyor belt as the vehicle is being crushed.

Why is it used?

The vast majority of vehicles crushed are smaller-sized consumer vehicles. Size-wise, mobile car crushers are more suited to this task because they are smaller and use less fuel per cycle.

History and Invention

Charlie Roy Hall patented The mobile car crusher in 1997 (US patent number US5655443A).

2. Car Crushing Machine (Dropping weights as a presser) (alt: Car Crushing Machine)

A car-crushing machine that drops weights onto the vehicle is known as a shredder because it breaks the metal into smaller pieces.

Powering a Car Crushing Machine

These car crushers also use hydraulic cylinders to power hammers. The cylinders, in turn, are powered by motors, which a diesel generator may power.

Why is it Used?

Shredder-style machines are an older style of car crusher. Many vintage models are still operating because they are sturdier than newer devices.

History and Invention

Alton S. Newell patented the car shredder in 1969 (US patent number US3482788A)

3. Baling Press (alt: Baling Press)

A baling press car crusher compacts vehicles horizontally and vertically. This makes for more compact logs.

Depending on the device, the crusher may also roll the scrap pieces so they don’t fall apart as easily. This has a lot of advantages during transport on highways.

Powering a Baling Press

Modern baling presses are powered by diesel generators that power electric motors. These motors help pressurize and depressurize hydraulic cylinders. The cylinders are used to operate the plates that crush the vehicle.

Other motors and conveyor belts roll the metal as it is crushed to generate a log shape.

Why is it Used?

Baling press car crushers are the most efficient in compacting for transport.

History and Invention

Allen B. Sharp and Richard Hull invented the first baling-style car crusher. This variant of the car crusher was patented in 1966, with US patent number US3266413A.

What is the power of a car crusher?

Diesel generators power motors that pressurize hydraulic cylinders. As pressure increases in the cylinder, attached plates compress the vehicle.

The hydraulic cylinders generate 150 tons of crushing force at over 2000 PSI.

Bigger car crushers aren’t always more powerful than smaller ones. Everything depends on the pressure the hydraulic system can put on the plate.

A smaller crusher with a more powerful hydraulic will crush the car faster and compact it more than a bigger one.

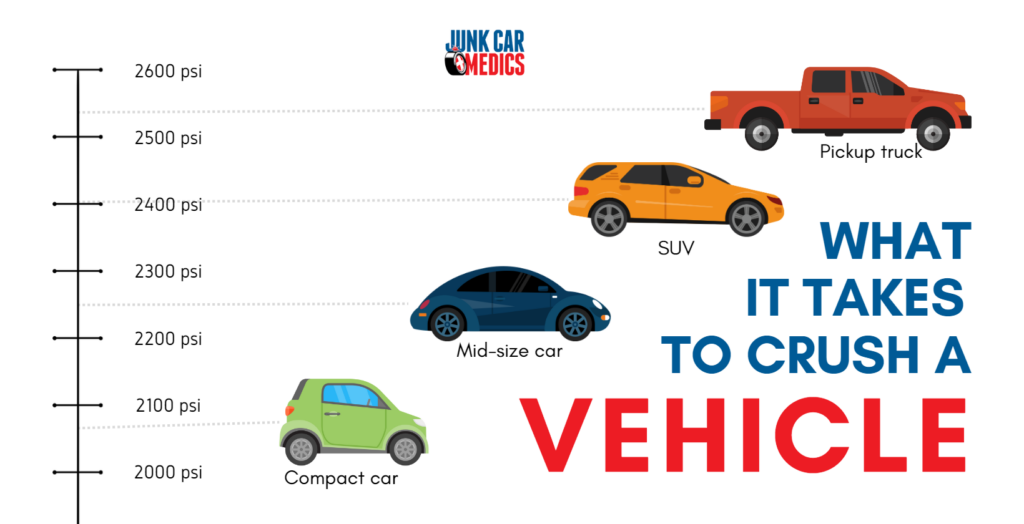

How many PSI does it take to crush a car?

According to answers.com, the PSI required depends on the vehicle's condition and structural strength. A car may take from 2000 to 2300 PSI. Trucks and SUVs might take as much as 2400 PSI.

Knowing the PSI required is important because car crushers use 8+ gallons of diesel per hour. Using a lower PSI for some vehicles can help lower costs for junkyard owners.

What is the electric consumption of a car crusher?

It is difficult to assess the electric consumption of a car crusher because:

- The make, model, and size of the motors used to drive the hydraulic system have different requirements.

- The pressure setting of the hydraulic system. The more pressure, the higher the electric usage.

The diesel consumption of a car crusher is easier to determine. For example, according to surplusrecord.com, a 2003 E-Z Crusher Logger Baler using a John Deere diesel engine JD6068P will use around 8 gallons per hour at 2000 rpm.

What is the role of a Car Crusher in Car Recycling?

A car crusher ensures a scrapped vehicle is at its smallest volume before transport for car recycling. This makes it possible to transport more salvaged metal using smaller trucks across highways and other roadways.

Here are some problems that are solved by a car crusher:

- Vehicles that have been in an accident or stripped tend to have loose bits of metal that can fall into the roadway. Once a vehicle is crushed, these bits of metal are secured within the compressed log.

- To travel over highways and other roads, there are limits on the vehicle's height, length, width, and anything it is pulling. Crushing vehicle hulls is essential for moving many pieces at one time.

How does a car crusher flatten the cars?

The process for crushing a car is as follows:

- The vehicle is stripped of fluids, usable parts, glass, and rubber.

- A crane, magnet, or forklift places the vehicle in the crusher chamber.

- Most modern devices start with crushing the vehicle from top to bottom. This may be accomplished from the top down along guideposts. Other devices may have a leaf configuration with two moving plates that fold the car in half.

- Some devices go one further step and crush the vehicle along the horizontal axis.

What vehicles?

Any motorized vehicle can be placed in a car crusher. Depending on the size of the vehicle, it may need to be cut into smaller pieces first.

What kinds of processes are used?

There are two basic processes used in car crusher equipment.

- The first uses plates powered by hydraulic systems to crush the vehicle.

- The second type uses hammers and wheels to break the vehicle into smaller pieces.

What happens to cars after the crusher?

After the vehicle exits the crushing device, the result is a compacted square or rectangle of metal. This will be sent off to a metal recycling facility and processed and repurposed.

Who is the inventor of Car Crushers?

Before 1966, vehicles were manually crushed with human labor and hammers. This process was very time-consuming and didn’t produce uniform results.

In 1966, Allen B. Sharp and Richard A. Hull of the Al-Jon Corporation successfully patented the Car Crushing Machine. It was one of the first to use a hydraulic system and plates to generate a uniform crushing action.

Over the next decades, this basic system was improved for increased mobility and power saving.

Aside from upgrades to the heart of the machine, there are also changes in how the machine is controlled. Modern car crushers are radio-controlled.

Future advancements may include using AI and other robotics to take the process from loading onto the crusher to preparation for transport.

Why is a Car Crusher important for Junkyards?

A car crusher is important to junkyards because it makes it easier and cheaper to transport materials that cannot be sold directly at the facility.

Compared to a square or rectangle, cars have a complex shape.

Suppose you have a container 8’ x 8’ x 8 and four vehicles with uncrushed dimensions of 4’ x 4’ x 4’. Let’s also say the car crusher can compact each one into a rectangular shape that only takes up 1’ x 1’ x 1’.

At most, 2 vehicles will fit in the container if they aren’t crushed first. It will also take 2 trips to get 4 vehicles to the recycling facility.

By contrast, when the vehicles are crushed, the container will hold all four vehicles plus an additional four. This saves 3 recycling trips, saving time and money for junkyards.

What is the difference between a Car Crusher and a Car Shredder?

A car crusher uses plates to compact the vehicle. A car shredder breaks the vehicle into smaller pieces before compacting those bits.

Here are some other ways they differ:

- Car crushers usually complete their cycle in less time than a shredder.

- Car crushers are more efficient because there are fewer plates to move when compared to hammers in a shredder.

Car shredders are a type of car crusher. Car shredders are different than scrap metal shredders because they focus on cars.

How much do car crushers cost?

The cost of a car crusher depends on the age and utility options. A used car crusher in working condition may cost as little as $30,000. Brand-new car crushers may start at $150,000 and up from there.

Many new junkyard businesses rent car crushers as needed to avoid maintenance costs on top of the initial purchase.

Experience renting different car crusher models also gives the business owner a chance for a hands-on assessment of fuel usage and efficiency. Later on, this can make purchasing or leasing decisions much easier.

Starting a car wrecking business involves many important decisions. Before you finalize your plans to rent or buy a car crusher, it helps to know what types are available and how they work.